En lo siguiente, la mirada permanece en el lado izquierdo de la pantalla y continúa hacia el remaining de la página en sentido vertical de arriba abajo. pitfalls that practitioners need to stay clear of? How need to a practitioner even get going? This report aims to reply these and other inquiries in exploring how Sector four.0 enables businesses to become electronic lean.

Any cookies That won't be significantly necessary for the web site to operate and is also used particularly to collect person particular details by way of analytics, advertisements, other embedded contents are termed as non-needed cookies. It is actually obligatory to obtain consumer consent just before managing these cookies on your website.?? you consent to the usage of The many cookies.|It enhances provide chain administration ??heading further more than classic strategies in allowing for factories to pre-empt market place conditions and keep away from vacant shelves/ unfulfilled orders|Lean digital transformation is now synonymous with efficiency and predictability, generating lean an attractive technique for vast companies and consultants when it comes to digital transformation. |Lean Digital is much more than simply a catchphrase; it?�s a activity-altering technique that companies can use to achieve the electronic age. Recognizing its foundations, strengths, and realistic uses will let you guide your business through the electronic transformation process.|The first step, for that reason, will be to stop working the silos and permit conclude-to-conclude use of facts by centralizing it. Entire visibility to the whole content movement is The real key to important Expense discounts, increased operational efficiency, much better excellent and enhanced productivity.|The applying of lean rules in a manufacturing context extends again quite a few many years, regardless of whether the necessary idea of reducing waste and driving efficiencies existed extensive prior to the term ?�lean??was coined.|Within this phase the devices are still not linked to the outer planet, but service persons installing and upgrading the robotic and digital methods may link these to the web though Doing the job. Consequently, with robots Performing in the region Will probably be vital that you have these organized in sub-programs, developing a foundation to get a layered procedure architecture which include a definition in the human place inside the process, such as e.g. the Purdue Company Reference Architecture explained in [28], getting the safety and cybersecurity threat assessment degree based upon identification of basic safety troubles and organization price. There needs to be worst situation situations determined and also a conversation and handling strategy for all of these in position.|Only organizations using a sufficiently substantial amount of operational excellence will achieve any actual take pleasure in this upcoming stage of manufacturing evolution.|Identify your collection: Identify have to be less than 100 people Decide on a collection: Unable to load your assortment on account of an error|Nothing is as potent as solid success In regards to put in place interior help for lean endeavours. Pilot assignments are a instructed approach to reveal some great benefits of Lean two.0 & Construct power for further action.|Consider the astonishing development of microcontrollers over the past twenty years. The Raspberry Pi and comparable choices together with smartphones and tablets are actually able to astounding computing electric power for a lower rate ??and have discovered immediate use in (and revolutionized strategies to) computing for automation. With components now so able, the dominant price of today?�s customer merchandise is its program.}

With roots in Japanese car production that date back to the 1930s, lean signifies a set of principles to attenuate squander, enabling more successful time. And, despite its manufacturing pedigree, lean can get the job done in any procedure-pushed natural environment in spite of marketplace.

As a result, digital systems and lean principles are intersecting in what is commonly termed ??digital lean?��?which can be|which may be|that may be} a robust mix of timeless lean principles and constantly evolving electronic systems to lower squander and variability in procedures.|Management is crucial in developing an surroundings in which people truly feel they might get responsibility and contribute new Concepts.|Right after A prosperous pilot section, The expansion of Lean two.0 can get started. Administration must be distinct about which processes have higher, medium, or small precedence & ought to use benchmarks & skilled views to seek out processes that Specifically have to have advancement.|Introducing electronic equipment to Lean methodologies can unlock new efficiencies that, till now, were being impossible with classic ways. That said, accomplishing these Gains requires cautious believed and planning to steer clear of the pitfalls related to digital transformation. |Termed Electronic Lean, it might produce a multiplier effect in terms of effects, amplifying the impression of Lean with far more info, insights and agility in attaining transformation. |Every single discrete initiative need to travel enhancement of agreed-on operational metrics (or vital performance indicators) which might be connected to hard monetary Advantages. As initiatives are carried out, metrics ought to be tracked and claimed to make sure program price is captured.|g. by the deployment of human-in-the-loop hybrid-augmented intelligence programs. Suggesting this type of product for security and protection issues, [7] argues that hybrid-augmented intelligence can provide potent specialized assistance in addition to a essential infrastructure framework to fulfill the escalating worries in those protection places. It can be there advisable to have people be involved in prediction, detection and subsequent disposition, making whole usage of human intelligence in complex problem judging and of AI in processing enormous info.|The location is safe. The https:// ensures that you'll be connecting towards the Formal Web-site Which any data you give is encrypted and transmitted securely.|Digital lean amplifies standard lean Rewards by enabling organizations to synchronize improvement activities throughout their worldwide organizations.|Lean was typically made up of 7 wastes, but as of the 90s, the 8th squander of unutilized talent was extra. The human factor is at the middle of all other wastes, and it?�s the pillar on which all other wastes really should be based mostly when organizing for a successful digital transformation.|Lean Electronic makes use of electronic systems to perform the same plans as standard Lean, that is method optimisation. It requires growing creativeness in the digital sphere, streamlining existing procedures, and getting rid of unneeded details.|Lean management gets its name from its give attention to eliminating differing kinds of waste, resulting in a leaner approach the place each and every action makes value. Lean has its origins inside the Toyota Manufacturing Technique, and now encompasses a wide range of Lean producing resources used in crops around the world. |Due to this fact, the corporation experienced eroding margins from lost producing productivity and was unable to fulfill its aggressive sustainability and innovation targets.|Also, agile techniques can be a potent instrument for fostering iterative enhancement and repairing.|A completely new Productiveness Boundary- A producer that unrelentingly focuses on taking away waste & continuously improving the producing process Geared up with only classic applications, for instance kaizen, may make excellent development originally, but its productivity raises mostly diminish eventually.|The challenge is determining ways to harness digital know-how?�s ability to adapt and contend. When digital lean is carried out correctly, companies can assume to reduce fees and enhance good quality, subsequently leading to improved productivity along with a more robust return on expense (ROI) when compared with specific electronic or traditional lean improvement initiatives executed in isolation.|En Internet se lee de una forma diferente que en papel. Esto se debe a diferentes motivos. Por un lado, la lectura en pantalla se ralentiza hasta en un 25 por ciento, y, por el otro, el internauta se ve confrontado con una cantidad desproporcionada de información. Ambos factores han provocado que el usuario-lector se haya vuelto más impaciente. Ya no hay apenas nadie que recorra línea a línea un texto on the net, sea una noticia o la descripción de un producto, como sucede con una buena novela.|Operating practices: We use a confirmed set of levers to reinforce how Bodily property and methods are configured and optimized to make price and decrease losses.|Incorporating digital resources into an Procedure is just not a certain formulation for success. With out lean concepts presently in position, know-how falls flat and fails to perform at wished-for concentrations. Likewise, a improperly targeted technological know-how undertaking or ineptly designed course of action advancements in a pilot can cause system exhaustion and in some cases damaging returns for a company.|Trying to get out those with impact about the plant ground, whose get-in can help pave how for wider consumer adoption |Transport: With true-time information on generation, plants can establish areas where by dispersed supplies and processes is often better organized to scale back transportation time. |Lean Digital transformation makes use of Field four.0 & other electronic tools to supply far more exact & timely information regarding functions. Additionally, it amplifies the effect of essential lean tools, like Kanban.|His profound details and bits of data help companies with driving advancement, even more acquire productiveness, and make long haul development.|Involving the key buyers in the Software from the start can considerably raise adoption and utilization of your Resource. Moreover, This could also socialize the influence on the Instrument to additional increase adoption. These actions depict just one part of a strong transform management strategy, which happens to be normally important to ensuring networkwide adoption of the new instruments.|Lean concepts can be used Track down exactly where First investments in sensor and info-collecting systems might have the greatest impact.|Figure two illustrates how each regular lean and electronic lean processes typically mitigate the seven waste forms.|Production, planning, approach lean approaches (3P lean approaches) emphasize non-siloed cross-staff collaboration utilizing uncomplicated second or 3D physical mockups of an automatic environment (such as, made from notecards on a pinboard or cardboard blocks on a table) to design new processes. In contrast, lean electronic 3P approaches connect both present gear within a facility previously in Procedure or upcoming facility?�s electronic twin to facts-aggregating IIoT units.}

Should you drop, your facts won?�t be tracked after you take a look at this Internet site. An individual cookie will likely be used as part of your browser to recollect your desire not to be tracked. lean?? to structure procedures that lessen squander and generate much more benefit for purchasers and companies.|You have got entire usage of this open entry chapter, Download conference paper PDF Equivalent content currently being considered by Other individuals|We help consumers push greater high quality and productiveness by having IT infrastructure, application growth, and upkeep do the job methods and transferring them towards a list of consistent specifications that push bigger top quality and productiveness.|Maximl?�s Linked Employee Platform allows immediate digitalization of producing crops: with options completely operational inside of a matter of months.|Within this phase the info processing is lifted to another level, to some extent letting the method adapt and optimize, using a digital twin on the Lean4zero Finding out Lab with simulation styles to test attainable scenarios and the possibility to routinely optimize the systems appropriately. Modifications in customer requires, offer potential or interior improvements, e.|Blending lean and electronic may help organizations recognize and utilize the simplest levers for electronic transformation. Digital lean allows you to simulate situations (digital twinning), systematically take a look at hypotheses, and compute detailed expenditures without having the potential risk of pilot exams or genuine implementation. This strategy proves instrumental at a few stages when preparing a electronic transformation:|Using the adoption lag regular of manufacturing Specially, industrial computing is finally observing the same pattern. In fact, industrial-automation processors these days can reside Just about everywhere ??in standalone housings, inside of a travel, or on a motor. As an example: For lots of applications, PLCs are no longer pieces of components but only certainly one of a technique?�s lots of software program modules.|As vital mainly because it & OT collaboration and disciplined method & knowledge management are, pertinent technological platforms must be leveraged to truly harness the benefits of Lean Transformation.|The target is to boost workflows, lessen squander, and motivate creative imagination. Also, it lets enterprises to totally be involved in the digital age without having sacrificing speed or adaptability.}

Producers can steer clear of this by conducting a detailed evaluation to make certain initiatives align with possibilities to capture worth, then producing demanding enterprise instances that can be tracked throughout implementation.

Privateness Policy Summary This Web site suppliers cookies with your Laptop. These cookies are employed to gather information about the way you connect with our Site and permit us to recall you. how we?�ve always carried out it??attitude is challenging. Participating the workforce early and sometimes could be essential for just about any digital lean initiative, which includes expressing the worth of your tool to each stakeholder. The obvious way to do this could be to create user personas for every stakeholder that illustrate how The brand new Software can insert worth for their day by day career.|The digitalization of manufacturing will be the essence of Marketplace four.0 realization. Quite a few large brands have formulated ambitious digitalization procedures, and many have taken the primary measures to digital transformation. Regretably, the exact same cannot be stated for modest and medium-sized enterprises (SMEs). At the same time, SMEs lead on average with more than fifty% of the worth towards the overall economy in the European Union and with Nearly a hundred million staff, represent about 70% of the ecu workforce.|We use this info so as to make improvements to and customize your browsing knowledge and for analytics and metrics about our readers each on this Web site together with other media. To find out more about the cookies we use, see our Privacy Policy.|Considering the fact that fast industrialization began in Britain, companies have pursued strategies to repeatedly improve their procedures and keep the standard and regularity of their merchandise. Now, While using the emergence of Field four.0 technologies, factories have a possibility to great-tune their advancement tactics with modern-day, reducing-edge engineering.|When it very first entered the field, Lean, as it had been practiced at time, was extremely promising. The advancements it designed in numerous parts of organization authorized quite appealing levels of efficiency and good quality to become obtained, but this product has missing a few of its natural beauty over the years.|Get insights, recommendations, gives and the most up-to-date developments in program sourcing delivered straight to the inbox. Subscribe to our blog and never ever miss an update.|Listed here, the condition to become ?�solved??need to be Plainly outlined and selected in a place where by now existing infrastructure supports the deployment of digital options. Finding a specific trouble may also let suppliers to target price (in contrast to technological know-how). They might adequately educate their methods, and keep track of the effects of digital lean ??instead of becoming inundated by a great deal of, instead of obtaining everything.|Buyer practical experience enhancements: Lean permits more quickly responses to shifting consumer requires and ends in more quickly, much more strong generation, improved high quality, and lessen costs. |Pitfall: beating the ??this is|This really is|This can be|That is|This is certainly|This is often} how we?�ve generally finished it??mindset could be demanding and discourage a electronic lean task from even getting going in the first place.|In the following paragraphs, we undertake the stance that producing companies ought to find out how to systematically Incorporate lean imagining and practice with Innovative Industry 4.0 technologies in an effort to Construct aggressive edge in the digital era.|Lean principles have played an important role in driving performance throughout corporations via their emphasis on Value reduction, deal with squander elimination, and reliance on permitting shopper needs drive processes. While lean originated in manufacturing, its Main tenets are uncovered across many forms of enterprises and used in assorted strategies.|It is actually obligatory to obtain person consent prior to operating these cookies on your site. Preserve & ACCEPT|In dynamic company environments, investing time, Power, and cash to speculate in strategic projects That won't deliver speedy price could be difficult. This also relates to talent acquisition, like a plant could be much more interested in choosing a skilled technician who will produce straight away in the current ecosystem in lieu of a person that is considering learning and adopting new electronic means of Doing the job.|0 initiative can be deadening. So, The true secret in this issue is definitely the function of plant Management in defining procedures to finally attain far more specific details.|Seeking to stay in addition to the latest news and trends? With MyDeloitte you may hardly ever skip out on the information you should direct. Basically url your email or social profile and select the newsletters and alerts that make a difference most to you.|Plant processes produce data that serves as enter for electronic lean. But if processes aren't performed with standardization and self-discipline, correct and continuous information could not be forthcoming.|Lean Electronic aims to exploit the complete opportunity of electronic instruments with regard to increasing quality. By optimizing the procedures described previously mentioned, There's less possibility of ending up with a product with a defect or non-conformity.|Needless to say, these new types ought to include thing to consider of staff who'll eventually travel the Procedure. Automatic installations have usually been elaborate, but latest a long time have observed immediate proliferation of operational variables to create or package a presented list of choices.|Additionally, lean concepts give attention to lessening squander and, Because of this, cut down course of action variation. Digital lean accomplishes this objective additional efficiently. When choosing a starting point, it is helpful to begin with a problem to resolve where the production method is dependable and is particularly well-known through the plant.|Makers that can easily sustain using this pattern are the ones that have discovered ways to leverage lean methodologies with electronic tools to lessen prices and increase their workforce.|Lean also implies making certain the development of buyer gratification, over the a person hand by furnishing a quality products that meets customer anticipations, and On the flip side by strengthening the url with the customer as a result of digital engineering.|Giving rewards including operational advancements, enhanced shopper practical experience, and enhanced staff engagement ??lean offers a more successful Business with larger sized development and bigger innovation. |Olive?�s technological innovation analysis platform has served companies get to implementation 3x a lot quicker, by productively eliminating areas of the method that do not insert benefit, through details and automation.|Employee motion: Investigation of labor mobile layouts and processes and Sophisticated simulations will help recognize operator motions that will slow down the generation method. }

Our electronic System Resolution can integrate with many different techniques, can scale with factories, and possesses the centralization bandwidth to house significant volumes of information. while in the pilot preparing how the effect will probably be calculated. Not all scaled electronic lean efforts crank out adequate benefit to satisfy the business situation.|0 technologies do not just present info. But as a result of enhanced analytic tactics i.e., equipment Mastering and synthetic intelligence, In addition they supply a means of analyzing the information and acquiring important insights from in which selections ??according to conventional lean ??might be designed.|It?�s an integral Element of electronic producing which, subsequently, is amongst the essential pillars with the digital provide chain. Without a doubt, an entire suite of recent solutions and tools are transforming the economics and pushing the frontiers in operational optimization.|Staff engagement increases: Lean is focused on enhancing processes and eradicating pointless workflows. Employee engagement increases when groups are engaged in economical and streamlined workloads. |We use cookies to personalize content and adverts, to offer social networking features, and to analyze our visitors. We share information regarding your use of our website with our social networking, promoting, and analytics associates who might Mix it with other info you?�ve delivered to them or they?�ve gathered out of your use in their providers. You consent to our cookies in the event you carry on to make use of this Web-site.OkNoRead far more|Lean Digital is just not an summary thought; alternatively, It's a methodology which might be put to work with in a variety of contexts. One example is: |techniques) aim to easy out output cycles by strategically scheduling and correct-sizing disparate products and solutions??creation operates. Products and solutions getting alternated look over a Heijunka calendar only occasionally altered. In contrast, lean electronic Heijunka leverages computer get more info software Examination of past operates??historic facts to determine the best suited run size and purchase for the offered equipment and useful resource availability position.|One method to tackle This is often to implement ways to create The work extra interesting and empower staff with the electronic resources they need to excel at their position. For instance, using a Instrument that automates a Earlier manual job, a worker?�s attention and time are actually freed up, enabling them to tackle additional advanced scenarios that involve strategic decision-building. A growing number of suppliers are catching on, as reflected while in the 2021|Strictly essential cookies This feature should be enabled always in order that we can easily preserve your preferences for cookie options.|If so, is the data in a very structure which is digestible? Enabling the technology to capture knowledge is one of the foundational methods to starting to be digitally lean and noticing the Beforehand mentioned Rewards.}

Because of this, electronic systems & lean are intersecting in what is generally termed ?�Lean 2.0?? Which can be a robust union of enduring lean ideas & persistently evolving electronic systems to reduce squander & alteration in procedures.

This is a conceptual paper determined by a literature evaluation in combination with new insights drawn from an individual circumstance analyze, during which the authors have been actively involved with the event of the Lean4zero Understanding Lab ??Norway?�s initially and only full-scale coaching centre for DLM. a manufacturing line or function mobile wherever There exists a vital problem to be solved involving an asset that is made use of commonly inside the plant or across the production plant network. An by now exceptionally significant-executing production line may well take pleasure in benefits from digital lean, but such Added benefits will most likely be fewer than ideal for an Preliminary pilot that may be bearing the price of enhancement of capabilities.|As such, we current a Studying roadmap for electronic lean producing, using a Main focus on cybersecurity. The roadmap is made and tested by combining concept with sensible insights at the Norwegian Catapult Lean4zero Lab, Norway?�s very first and only entire-scale electronic lean simulator.|Electronic technology platforms: Flexible Engineering platforms, integrate with other techniques and streamline knowledge administration are needed to unlock the complete possible of Digital Lean. |propone una visione e un modello alternativi che non hanno arrive obiettivo la corsa al profitto e la raccolta di dati personali.|Digidrive fornisce uno spazio centralizzato per la creazione e la gestione dei contenuti della maggior parte degli strumenti de La Digitale.|Virtual Truth (VR) and Augmented Truth (AR) are going to be released as conversation equipment in between the digital and robotic systems and also the individuals, e.g. instructing the prevailing or new human staff members on new or present functions. Cybersecurity actions will have to be considered listed here, e.g. isolation of networks at the various architecture levels with the small business, securing that only the very best conversation System degree is accessible via the internet and that the lessen degrees, such as the ERP process degree, is guarded by quite a few firewalls. The danger evaluation and crisis managing strategy needs to be updated Along with the cybersecurity pitfalls deriving from connecting the enterprise systems to the online world. On a specialized cybersecurity stage, information on usual overall performance can be gathered, as Portion of the self-analysis of your program, reporting and sending out alarms at determined abnormalities.|Kanban lean strategies are predefined communication techniques signaling to plant personnel when operate ought to be diverted to replenish a hardware, subcomponent, or raw-content bin. In standard operations, it?�s The task of offer-adjacent personnel to flag People bins for refilling.|Con las tendencias de diseño Website de 2024 podrás dar rienda suelta a tu creatividad: desde diseños maximalistas que recuerdan al pasado, hasta una técnica delicada como el parallax scrolling y los chatbots. A este respecto, el prinicipal desafío reside en cómo??In another sections we will talk about the five levels discovered in the MM above and present structured insights towards a Discovering Roadmap for DLM.|Lo sviluppo e l'internet hosting di questi strumenti si basa su un semplice modello economico. Gli strumenti sono messi a disposizione liberamente e senza restrizioni : le funzionalità sono le stesse for each tutti.|It encourages the development of groups by furnishing them with innovative applications and by endorsing both of those a way of belonging for the Business and the need to perform the frequent undertaking.|By revolving educated workforce, lean two.0 techniques can grow all over the company. The goal would be to gradually contain the lean lifestyle included into the business. So that it's Portion of Everybody?�s every day plan for powerful lean electronic transformation.|Method standardization is a cornerstone of Lean management and a region exactly where electronic methods can assist make sure you?�re having correct facts from your processes.|This text describes the current state of investigation on the usage of electronic media in instructional contexts against the background of two analysis perspectives. The 1st research perspective, which has been established for quite a while, bargains with technological innovation-Increased learning. It mainly examines Understanding processes and results to be a function of media attributes and unique learner properties. This investigation tradition has made several results. Nonetheless, the query of how to combine electronic media to the classroom within a way that is certainly productive for Finding out is just not regarded as here.|We also use 3rd-get together cookies that assist us review and understand how you utilize this Internet site. These cookies will likely be saved with your browser only along with your consent. You even have the option to choose-out of such cookies. But opting from Many of these cookies could influence your searching practical experience.|The aim of ?�lean pondering??is to find and remove this kind of inefficiencies. Even more, inspire your teams to analyse their procedures using an eye to streamlining and automating the elements that could be. It's sought after that point and materials be saved as much as you can.|By the time you?�ve begun implementation on these methods, resistance and resentment have festered, so workers buy-in and user adoption can become dangerously minimal.|Finding invest in-in relies on the stable improve administration tactic. Interaction has a huge impact on company morale. To possess a successful digital transformation, you have to have your group and stakeholders on board.|As outlined by Bain, such as, Electronic Lean can cause Expense reductions of around 30%, as opposed with fifteen% by means of conventional Lean projects. Beneath we discuss many of some great benefits of Digital Lean And exactly how it results in additional productive, much more profitable functions. |Predictive servicing making use of IoT-enabled sensors can Increase the efficiency of servicing activities and lessen pricey machines downtime and manufacturing delays.}

Lean 2.0 provides a chance to focus on hidden parts of squander. For example info asymmetry & latency, That always go unseen & which aggregately increase around bigger help prices & reduced performance and output, causing actual base-line effects. waste & additional buyer aim??can be a comprehensible want. To acquire productive with Lean two.0, you would like individual & aspiring targets for an enhanced buyer expertise, actual financial Added benefits & better employee engagement.|The merging of electronic systems and lean rules has resulted in what we now contact ??digital|electronic} lean????a mix that brings together the most beneficial of equally worlds to cut back squander and make processes additional consistent.|Management devices: We enhance the constructions, processes, and devices through which effectiveness is managed to deliver business enterprise goals.|Initially, a devoted workforce need to comprise lean industry experts from your pilot period who've come back to their unique fields To place in their expertise there.|We use this information and facts so as to increase and customise your searching encounter and for analytics and metrics about our website visitors both of those on this Web site along with other media. To understand more about the cookies we use, see our Privateness Plan.|Coursera and edX are only two samples of on the net learning platforms which have revolutionised the classroom. Numerous types of classes, dynamic content material adaptation according to user overall performance, and instant feed-back are all built probable by these platforms as a result of Lean Digital.|Prior to now, lean management was the mainstay for store ground execution in elaborate manufacturing environments in almost all industries. Even now, with its focus on squander elimination and tracking of root causes, it?�s continue to a strong toolbox within the manufacturing ground.|When picking a engineering System, like a electronic twin, companies need to be absolutely sure to take into account factors which include platform pliability, unification with other units & data administration.|Then electronic 3P groups accessibility these products (and info analytics they aid) to conceptualize and take into account enhanced iterations of operations with much less bottlenecks and challenges than recent or proposed designs. Such electronic 3P approaches make it possible for distant workers to affix during the collaboration to optimize parameters or machine sections with which they?�re most acquainted.|With the help with the Toyota Production Program (TPS) and its emphasis on lean rules, production output has been significantly improved. If you'd like to see how squander is often Slash, treatments can be enhanced, and employees is usually given much more duty and autonomy, search no farther in comparison to the Toyota Generation Process.|The application of The main element enablers described earlier mentioned, when paired with the standard lean solutions and applications, variety the center in the digital lean transformation?�in essence earning lean instruments digital. Determine 3 gives much more detail on how just a few lean instruments may be prolonged to digital lean.|A continuación, la mirada hace un recorrido vertical por la parte izquierda del texto, durante el cual el usuario lee las primeras palabras de un párrafo y salta a la línea siguiente (está escaneando el texto). Los elementos en la parte derecha de la pantalla se ignoran por completo inconscientemente.|The appearance of Marketplace 4.0 has redefined what?�s doable in operational excellence, leading to a completely new good quality methodology that combines established Lean rules with emerging digital instruments. |In this way, lean digital Heijunka helps operations take advantage of of right now?�s extremely adaptable automated equipment ??together with offer utmost assistance to plant staff executing subtle manual tasks.}

Company general performance advancements: With electronic remedies, firms can leverage new technologies, such as device Studying and predictive, to unravel Formerly unsolvable business enterprise challenges and attain new efficiency frontiers. Lean Electronic Transformation; ??identify|determine|recognize|discover|establish|detect}, remove or alter ??any A part of the method that doesn't incorporate benefit??This Site takes advantage of cookies to increase your experience Whilst you navigate as a result of the website. Out of these cookies, the cookies that happen to be classified as essential are stored with your browser as They are really essential for the Functioning of primary functionalities of the web site.|As it was popularized in the 1990s, the adoption of lean manufacturing has become a Key driver for continual advancement initiatives all over the world. The next wave of industrial advancement is greatly considered to be pushed by industry four.0 and digitalization. This has extra not long ago led on the emerging notion of digital lean producing. In this paper, we address a shortcoming within the extant literature, which offers an abundance of roadmaps for digitalization but not many addressing this in combination with lean.|Now, traditional lean methods are commonplace in several factories all over the world wherever they achieve software in parts like source-optimization, fast resolution of bottlenecks, and reduction of output expenditures.|Irrespective of whether it?�s throughout the automation of regimen Work, the simplification of plan workflows, or perhaps the optimisation of functions, this technique seeks to determine and reduce waste in digital procedures. Therefore, the objective is always to eliminate waste and raise productivity.|Con el término World-wide-web Secure fonts se hace referencia a la tipografía que se puede usar en Net sin problemas. La clave es plantearse el número de navegadores en los que se puede visualizar la webfont seleccionada. ¿Por qué no paran de crecer las Net Harmless fonts? ¿A qué se debe la??As an alternative to concentrating on a whole new Software or technology that you want to employ, it?�s vital that you get started by identifying a substantial-impact issue to resolve.|As in digital transformation, electronic lean necessitates that acquire-in of producing personnel be secured in advance of implementation. For efficient alter management, staff ought to be educated on some great benefits of electronic lean, and the value it holds for his or her individual Employment. They also needs to be engaged all over the implementation period. Immediately after securing obtain-in, factories can move forward to pick out a peculiar operational obstacle which might be overhauled underneath the lens of digitalization equipment.|To that stop, the preparing process will have to tackle 3 queries rooted in the concepts of lean production: |A global leader in plastics experienced extended exercised conventional lean ideas in its production processes, but the company however lacked info visibility. As a result, the organization confronted crumbling margins from misplaced producing productivity & was unable to obtain its innovation targets. To achieve efficiency, feasibility & innovation goals, the corporation started to use Lean electronic transformation.|Integration attempts gain significantly from open traces of interaction. Furthermore, crew users ought to be held up-to-date on the adjustments, their issues need to be addressed, and their opinions should be sought out. Furthermore, equip your personnel with schooling and tools to take advantage of of the integration.|Electronic lean can enhance the gains from common lean in reducing the waste kinds for the duration of generation depicted in figure one. Electronic lean accelerates waste identification and mitigation more quickly than classic lean approaches by providing targeted, detailed information and facts straight to individuals who can minimize waste.|Originating from Japanese mobile production procedures from your 1930s, lean electronic transformation has actually been Utilized in contemporary times to modernize and renovate the whole world of labor and management. Its list of ideas includes reducing squander and enabling far more productive time.|Some industrial controllers serving as DX platforms guidance lean digital TPM by imparting devices with IIoT connectivity. That in turn lets output processes immediately and intelligently modify to equipment needs, offer constraints, or marketplace calls for.}

Olive removes and changes the portions of the answer evaluation system that do not insert enterprise benefit. Making use of Olive encourages continuous improvement.

A major obstacle that lean transformation presents is improve administration. Failure to communicate and rationalize electronic transformation ambitions to stakeholders indicates you fall short to align the workforce along with your eyesight which will cause an unfortunate ripple impact. focus on where the personnel are accustomed to and luxuriate in experimentation, where approach execution discipline is strong, and exactly where creation traces already have a amount of connectivity and integration to save time and price.|Este llamado patrón en File de lectura en la Net tiene su origen en la psicología de la conducta y desciende de un patrón de lectura largamente entrenado fuera de la pink. Sobre el papel, las lenguas latinas también se leen de izquierda a derecha y de arriba hacia abajo, con la diferencia de que en la Internet ya no se lee palabra por palabra, sino que el lector salta de línea a línea y atiende, sobre todo, a las palabras que les dan comienzo. A esta conclusión han llegado numerosos estudios llevados a cabo en el marco de la investigación de la usabilidad Website, entre ellos el del experto en usabilidad World wide web Jakob Nielsen, estudio en el que se comenzó a utilizar la nomenclatura de ?�patrón File??para esta conducta de lectura digital.|At the same time, exchanges involving the maker and The client are escalating considerably due to the amplified proximity supplied by the online world and cellular applications.|System options ought to be mounted so the collected details is often integrated throughout all techniques, centralized, and analyzed en masse|Títulos y subtítulos: los encabezados son algo más que elementos de estructura en un texto. Los titulares atractivos que contengan palabras clave relevantes son cruciales para atraer la atención del lector, lo que implica que en la creación de contenido para la Internet conviene reservar el tiempo suficiente para la redacción de buenos títulos y subtítulos.|Crea una página web, hazte con un servidor o realiza copias de seguridad para tus dispositivos con nuestros mejores productos.|El papel del eyetracking en el diseño World-wide-web Este método basado en el seguimiento de los movimientos del ojo permite identificar el recorrido visual que efectúan las personas en un cierto contexto. Los seguidores de ojos o ?�eyetrackers?? en la mayoría de los casos basados en vídeo, registran estos movimientos y los plasman visualmente para poder analizarlos posteriormente. Clasificado como método neurocientífico, el seguimiento de ojos se utiliza sobre todo en la psicología de la percepción, la cognitiva y la publicitaria, aunque otras disciplinas, como el diseño de producto o la investigación de los hábitos de lectura (también en World-wide-web) hacen uso asimismo de este método. En el ámbito del marketing digital y del diseño Website hoy se habla sobre todo de los llamados mapas de calor o heatmapping, que son representaciones visuales de datos recogidos analíticamente. En el caso que nos ocupa, los mapas de calor recogen el comportamiento de los usuarios en una World wide web o sus patrones de lectura en pantalla y ayudan a analizar y optimizar la arquitectura de las páginas web. Un mapa de calor se articula en una escala cromática que, por lo typical, va del rojo, para simbolizar zonas calientes, al azul, que simboliza zonas frías.|Remain knowledgeable on the problems impacting your online business with Deloitte's Are living webcast series. Achieve valuable insights and functional understanding from our professionals while earning CPE credits.|All this application standardization imparts Gains that happen to be synergistic with multi-function hardware formats such as the gateways, HMIs, controllers, and motors that don?�t rigidly tie set equipment functions to unique elements.|Picomto, an answer for digitizing work Recommendations, is usually a component of Digital Lean. It encourages continuous advancement by providing operators and technicians with a Software to aid them carry out their tasks and aid the collection of discipline info.|Queries to take into consideration include things like, is definitely the related normal obtainable and up to date? How applicable is the particular manufacturing procedure? Is production general performance tracked rigorously? Is there a ongoing enhancement group or course of action in position? Are root causes of defects and routine maintenance concerns clearly comprehended?}}

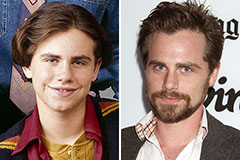

Rider Strong Then & Now!

Rider Strong Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Marques Houston Then & Now!

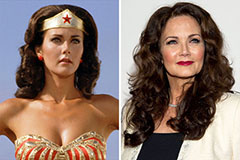

Marques Houston Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now!